Dave Hartzell, AF6KD approached me with the idea to build a feed for doing 23cm EME. We discussed the OK1DFC Rectangular Waveguide Septum Transformer specifications (see Zdenek's EME page for in-depth info). A thorough simulation and analysis of the design has been done by W1GHZ.

We were both capable of building this design. But as we thought about the process of acquiring the raw (aluminum sheet) materials and then how we could effectively cut, bend, and fabricate it (inexpensively), I wondered if we could enlist the help of a real machine shop. We were also interested in doing a prototype of something that we could more readily replicate. The photos and other info provided here are the result of our constructing three prototypes.

There are quite a few shops out there, and I found

emachineshop.com,

with their easy-to-use software, and real-time price

estimating particularly helpful.

I could iteratively select various materials (thickness, types, etc), and see

how they would impact the manufacturability and cost.

While the price on volume quantities was attractive, even

relatively small quantities seemed reasonable for prototype

and test purposes.

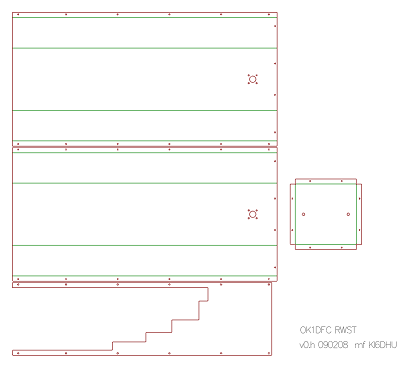

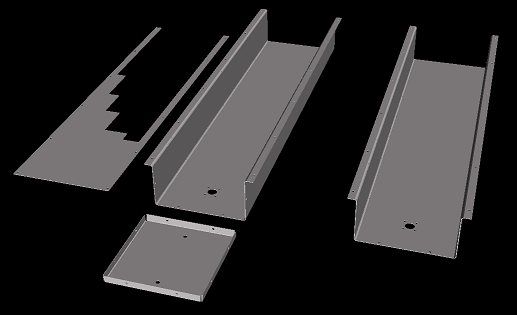

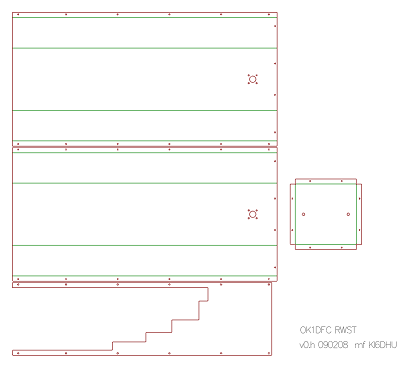

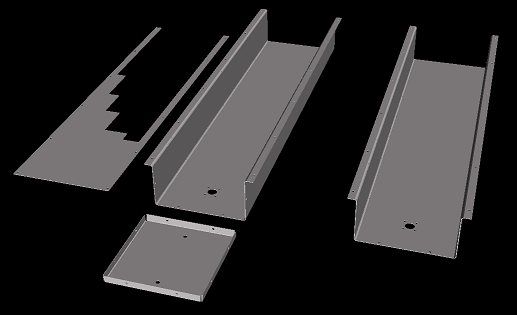

To show just a little about the emachine shop interface, here

is a two dimensional drawing and a three dimensional representation.

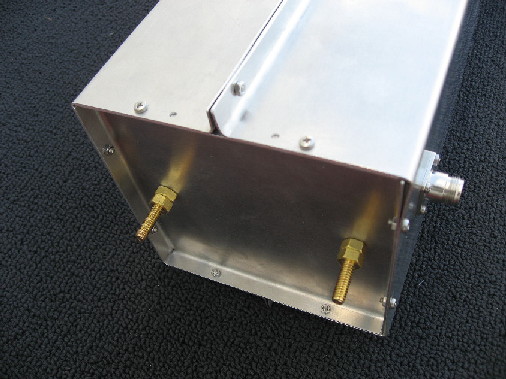

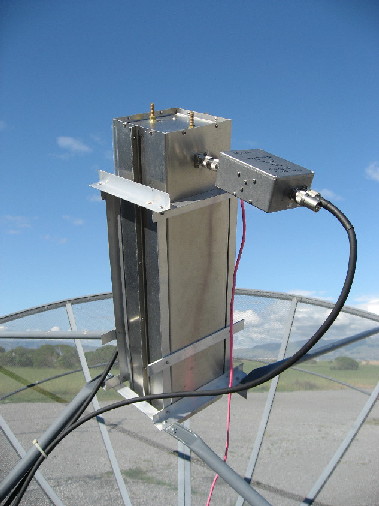

To the extent possible, all dimensions and materials use metric measurements (from OK1DFC's drawings and table). A key change I made was to use thinner material and fewer screws. The body material is 1.02mm 5052 aluminum. The back plate is made of the same material, and thus has folded edges with through holes. The assembly bolts and nuts are 3mm stainless steel. I did relax the metric constraint, and used 1/4" brass screws for the tuning rods. I would have used metric, but 6mm metric brass screws were not as readily available as the other parts. Custom machining tuning rods for the small number of parts we needed wasn't cost effective.

The N connectors are Amphenol Connex (172119), and the monopoles were constructed from 3/16" brass rod (again, because that's what I could easily get). I cut the brass rod to 37mm, drilled a hole in the center just deep enough so that it could be soldered onto the N connector. Once installed, the distance between the inner side of the feed and the tip of the brass rod is 43mm.

As seen here in the prototypes, I tapped the back plate for the tuning screws. I knew when I used 1mm material for the backplate, it wasn't really thick enough to provide solid threads, and another solution would ultimately be needed. An improvement in future versions will use a threaded brass insert that can be tapped for either 6mm or 1/4" screws.

We were very fortunate to have the assistance and

encouragement of some other local EME enthusiasts:

Goran AD6IW, Jim N9JIM, and Steve KB8VAO.

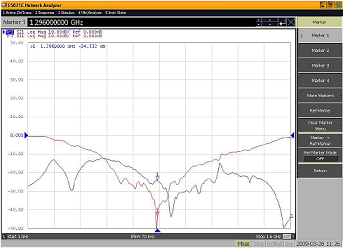

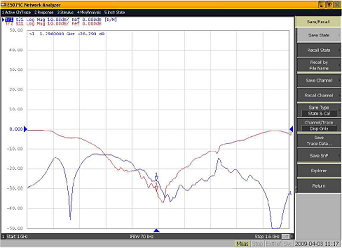

In particular, Goran provided tuning and analysis using

an E5071C Network Analyzer. The initial analyzer results are

displayed in these graphs:

prototype 1, port 1

prototype 1, port 2

prototype 1, port 2

prototype 3, port 1

prototype 3, port 2

prototype 3, port 2

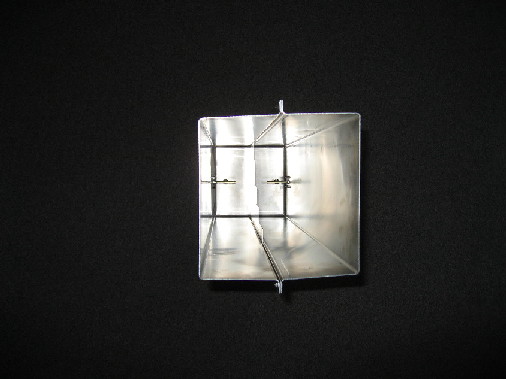

Here are some images of our feed (click to enlarge picture)

Assembled, back view

The monopoles

Side view

Tuning rods

Feed mounted on our 3m dish

Two views of our dish:

Looking East

Looking North

(note AF6KD's 2m beam w/ AZ/EL; works JT65 EME)

Are you interested in more information?

Please drop me a note:

fosterm ''at'' sonic.net