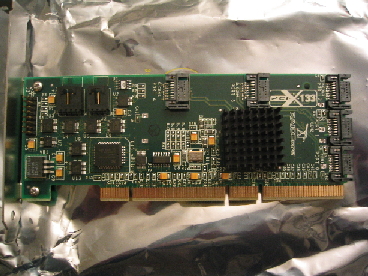

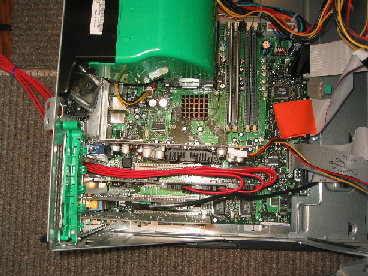

The RC4852 supports the extended 64-bit PCI-X bus, but works fine in

less expensive motherboards with 32-bit PCI bus. Five of the SATA

connectors are on the front, three on the back side of the board.

RAIDCore has chosen to give hardware assist just where it’s needed, and

puts most of their logic in the software that runs on the host

CPU. This design means that as you upgrade your CPU and

motherboard, you automatically upgrade the performance of your RAID

subsystem. It also means they should be able to more readily

enhance some of the subsystem’s capabilities, since doing so generally

won’t mean new hardware.

The SuperMicro CSE-M35T provides all the hardware and cables to install

in 5.25” drive bays and extend disk activity signals to LEDs.

It was quick and simple to install the disks in the quick-release

brackets that are integral to the CSE-M35T. The SATA disks, like

SCA SCSI disks, provide power and data connections in a hot-plug

capable design. There is no cable or adapter between the chassis

bracket and the disk: the disk connects directly to the chassis

backplane.

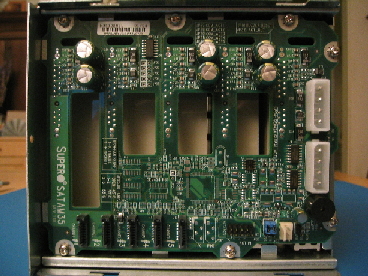

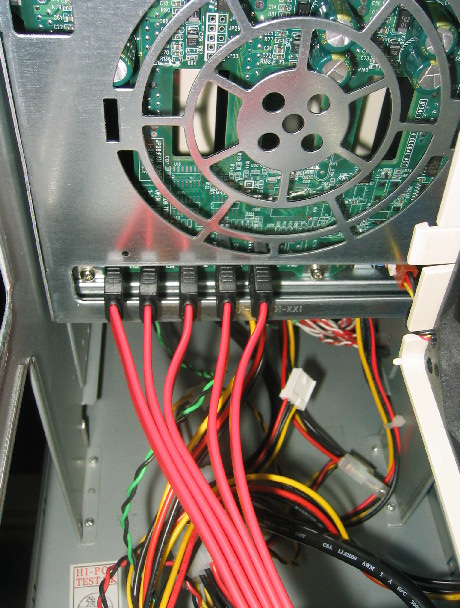

A look inside the back cover of the CSE-M35T shows dual power

connections, the SATA cable connectors, and header pins for disk

activity LEDs. Also note the large rectangular holes in the

printed circuit board. These are important: it’s how the air is

drawn off the drives and exhausted toward the back of the cabinet.

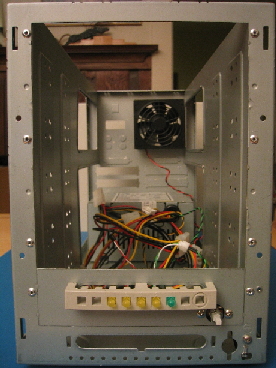

With the back cover and fan re-installed, you can still see the SATA

and power connections. The fan shown is Sanyo Denki 109P0912H202:

a 55 CFM fan that runs at 2900 rpm and produces a whopping 36

dbA. I cannot blame SuperMicro for choosing this fan. It

will definitely keep five drives running cool. They also probably

intend their chassis to spend most of it’s time in a noisy computer

room setting, not a quiet home office. I replaced the Sanyo Denki

with a SilenX SX-092-14. This fan only pushes 36 CFM, but also is

a nearly inaudible 14 dbA. I replaced the generic fan that came

in the salvaged cabinet with a SilenX 80mm thermistor controlled fan –

it will get noisy when it’s warm in the cabinet, so should function as

a early warning that I need to do something different.

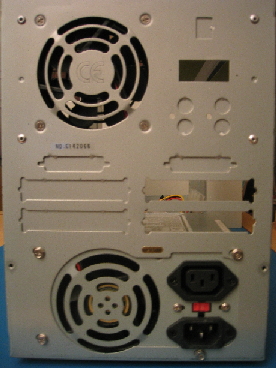

The cabinet was salvaged from some previous use, so had an ID switch

and SCSI-2 connectors, all of which were removed for this

application. I figured that even if I had to get a new power

supply, the $7 I spent was a great deal on the sheet metal frame

(ultimately, everything worked just fine - no replacement needed ).

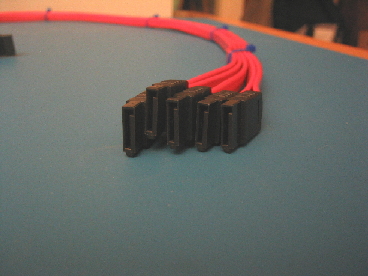

To reduce the unruly mess that all the thin, but stiff SATA cables

would create, I made a 5-cable bundle (I’ll make another 3-cable bundle

when the time comes to add a three drive chassis and disks). If

you’re doing this, be sure you line up the cable end keying, as shown

in this closeup of the end of the bundle. Also, take care if

you are using tie-wraps, as I did. They should be just snug, not

tight. Otherwise, you risk affecting signal integrity (RAIDCore

customer support confirms this). An alternative to tie-wraps

is electrical tape.

One end of the bundle connects to the backplane in the CSE-M35T

The other end of the bundle connects to the RC4852, installed in the PC

The back of the assembled cabinet shows the cable bundle passing

through one of the open slots previously used for a SCSI cable

connector.

I tie-wrapped the bundle to the cabinet at this opening, as a

strain relief.

I thought about using the 3ware SATA-to-firewire cable

adapters, so I didn’t have to have a single hard-to-disconnect cable

set chaining the PC and external cabinet together. Between not

having enough free PCI blanks in my PC and the additional problems the

extra cabling and connectors could cause me (not to mention the added

expense), I quickly extinguished the thought.

With the disks installed, the cabinet looks like it was made for

this. Leaving the (missing) blank open will help some with

airflow, and in this case, function is more important to me than

cosmetics.

Activating the Array – The Software

Installing the software from the CD went without a hitch. The

RC4852 comes with a comprehensive Users Guide (in PDF). Although

I was impatient, it was worth reading through it. They offer two

interfaces for array configuration, one BIOS level, the other a GUI

that runs under Windows. If you were setting up an array that was

going to comprise the system boot disk, you’d need to do the

configuration from the BIOS interface. Since I was just adding an

auxiliary drive, I was able to perform all the steps from the

GUI. I setup the RAID5 configuration to span across all three

disks. I had originally thought I’d be able to use their

“spanning spare” technology, but it turns out I’d need a fourth disk

for that. As easy as it is to get replacement disks, I think I

can risk running without a hot spare or spanned spare for now.

Once setup, I told it to initialize the three disks and create the

array. Be prepared for the time this process takes. It’s

analogous to a low-level format (even though that’s not what it’s

doing), and scales according to the size and number of disks. It

took about 8 hours on my setup. Once that completed, I decided to

run a “check consistency” (sometimes when working with fresh bits and

bolts, I tend to be paranoid). That took about 2.5 hours.

The check is in progress in this screenshot:

Then, I had Windows format the “disk”, the result is a single 295 GB

drive G:. Recall that in RAID5, one disk worth of capacity is

allocated to parity (even though the parity is striped across all the

disks). So, three 160 GB disks is really only 320 GB of space,

and with some filesystem overhead, 295 GB looks about right.

Time to exercise some of the features. I copied several GB’s

worth of content to the new filesystem, and began playback of the

video. To simulate a genuine disk failure, I pulled the second

disk (“disk 01” in the array nomenclature). A popup box notified

of the status change, and a glance at the management GUI confirmed the

condition.

All the while, the video continued playing with no glitches or

hiccups. So far, so good. Now, simulating the “repair”.

I had thought that I’d be able to reinsert the disk, tell the

controller to “rescan” the drives, and I’d be quickly back in full

operation. I assumed this because I’d been careful not to write

anything to the disk during this failure. This simplistic view

turned out to be false. That’s okay, it’s just that recovery took

longer than I thought it might in this instance.

A reinsert of the disk generated a popup box.

As instructed, I performed the rescan. The system sees the disk,

and recognizes that it is part of an array: note that Disk 01 shows

zero space available.

But, the array is still in critical state, and there is no active

rebuild or recovery task working toward fixing that state.

I proceeded to reinitialize Disk 01. This wipes out all the array

information on the disk, and thus, makes it look like an unused

disk. Doing so also changed the list of disks that the array knew

about: Disk 01 is now listed as “missing”.

I would have thought I could then request a “rebuild” of the array, but

either the sequence of events I had followed, or the support for that

(direct) approach isn’t fully there. In any case, I decided to

try the “transform” feature. I wanted to exercise this

functionality anyway, since I do expect to use it in the future when I

add disks to the array.

UPDATE (7/04): RAIDCore customer support (Jeff Huber) suggests that

I could have accomplished this step more easily by right clicking

on the failed disk, then selecting "initialize and set as ... spare".

Once I did a “commit” of this transformation, the online conversion

from the critical disk-missing array to the new three-disk

configuration commenced.

In about eight hours, the rebuild was finished, and all was well again

with the array.

For a significant portion of the time the rebuild was taking place, I

continued to use the system for text editing, email, and

browsing. I also periodically played some video content off the

array, watching and listening for glitches or hiccups. I didn’t

observe any. The cpu utilization during the rebuild was generally

about 20%.

I should also mention that during the rebuild, I had the array’s write

caching turned off. I did this for a couple of reasons. I

wanted to know a worst case scenario for a rebuild, and I wanted to see

how it impacted what I would consider typical use conditions if I left

write caching off all the time.

I’ve done some informal testing since the original configuration

testing, and the write caching seems to get about a 10-fold increase in

write speed. I haven’t taken the time to see if it provides a

similar speedup in the rebuild, but I suspect it would have a

substantial impact.

The Cost

At the outset, I wanted this to be an affordable solution. I

didn’t expect it to be low cost. One giant disk would have been much

less expensive.

| RAIDCore RC4852 | 350.00 |

| SuperMicro CSE-M35T | 150.00 |

| (3) Samsung SP1614C | 345.00 |

| (8) 1m SATA cables | 48.00 |

| (2) SilenX fans | 35.00 |

| 5-bay cabinet | 7.00 |

| TOTAL | 935.00 |

| As built $/GB for 320 GB capacity | 2.92 |

| (2) additional Samsung disks | 230.00 |

| TOTAL | 1165.00 |

| $/GB for 640 GB capacity | 1.82 |