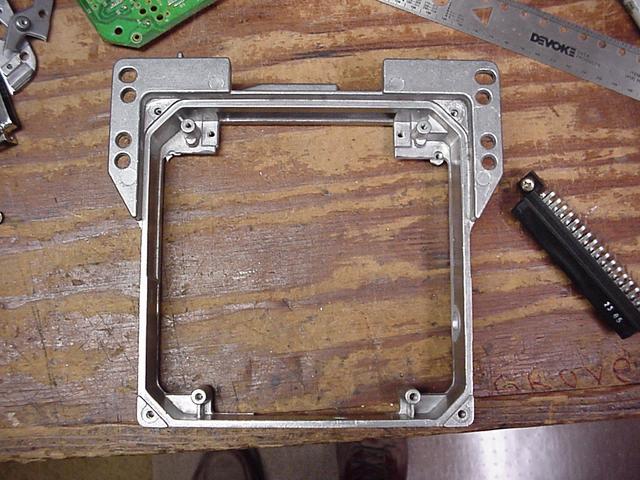

This is what we started with. A Bosch

case out of a BMW.

|

|

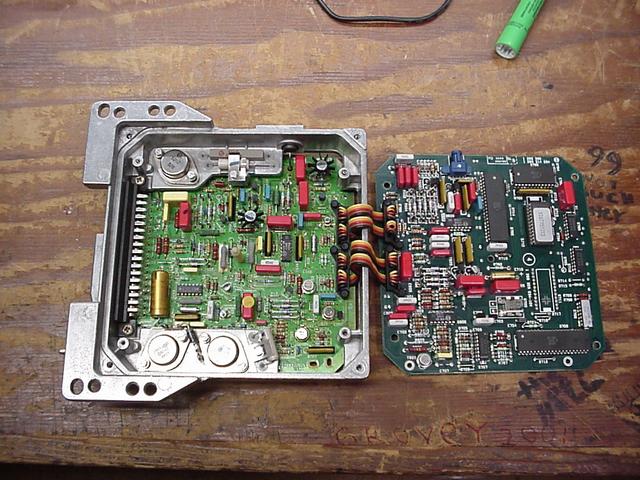

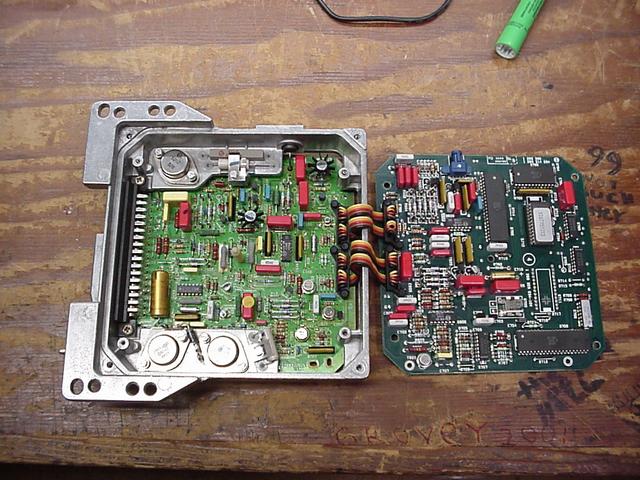

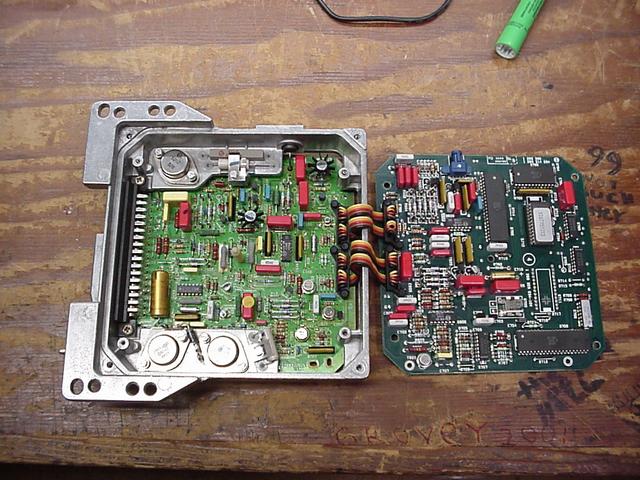

| Here the two original PCBs

are split open. All through hole

technology here. A very labor

intensive design with all the hand

padded resistor stacks.

|

|

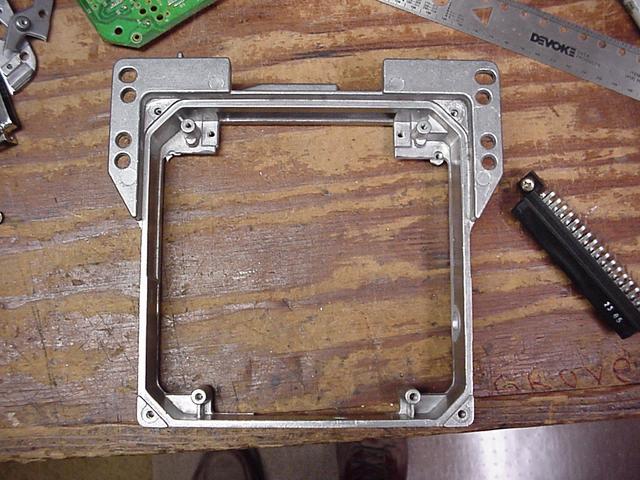

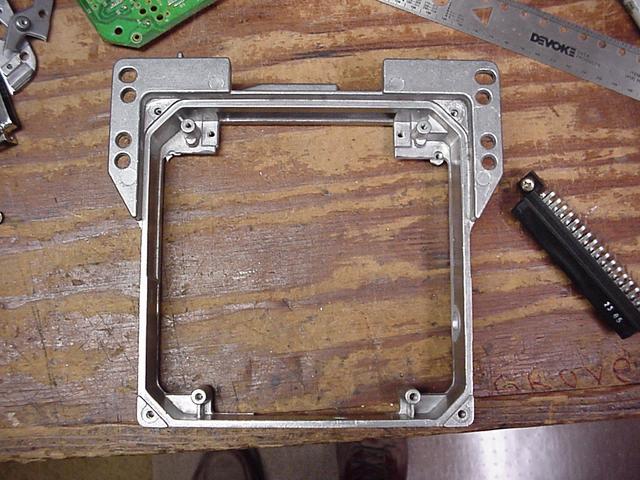

| This is what it looks like with

the PCB boards removed. You

can see the convent .5" hole in the

side of the case where the barro sensor

hose bib will stick out.

|

|

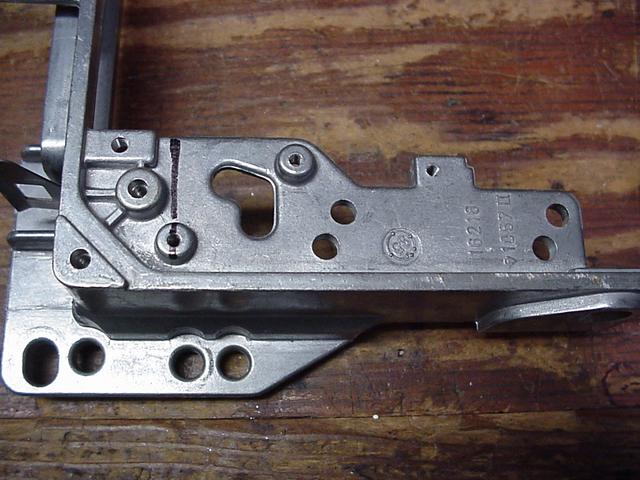

| Here I have marked where to take

off the old features that used to mount

the TO3 transistors. Left enough behind

so that the bosses that will hold the new

PCB still have some meat around them.

|

|

| Right side rough cut off the mill.

Cleared the extra material around the

barro hole also. |

|

| Removed the extra material from

the outside of the case also around

the hole. This hole originally mounted

a large press-in diode. |

|

| The other side of the case. All

the extra flashing I will remove with

a fine 3M disk to give the TO-220

driver transistors a good flat mounting

surface. The vertical step in the thickness

of the wall I will have to work around

in the layout. |

|

| What it looks like after the

mill work. |

|