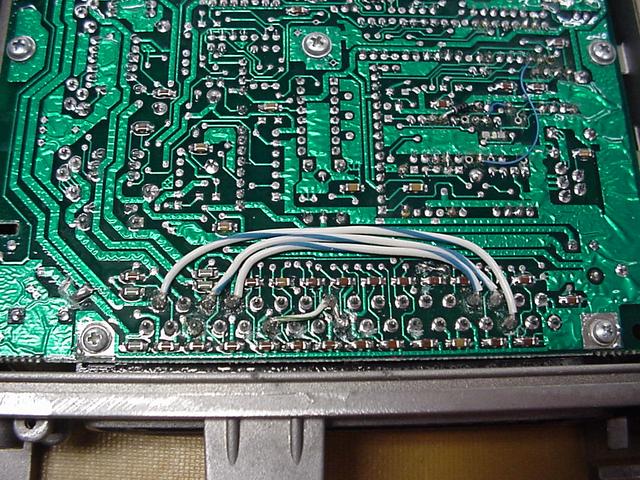

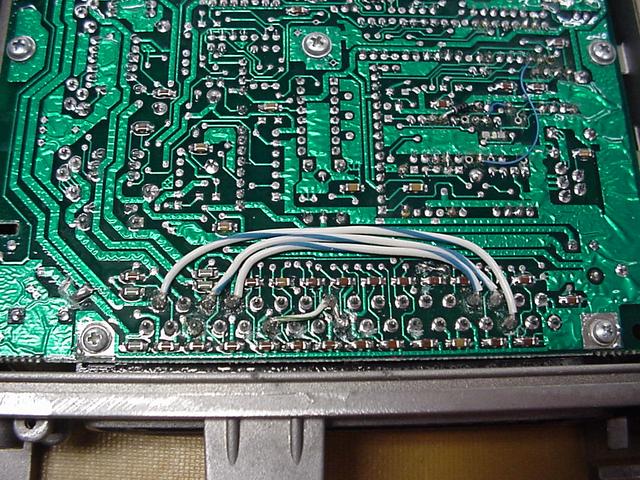

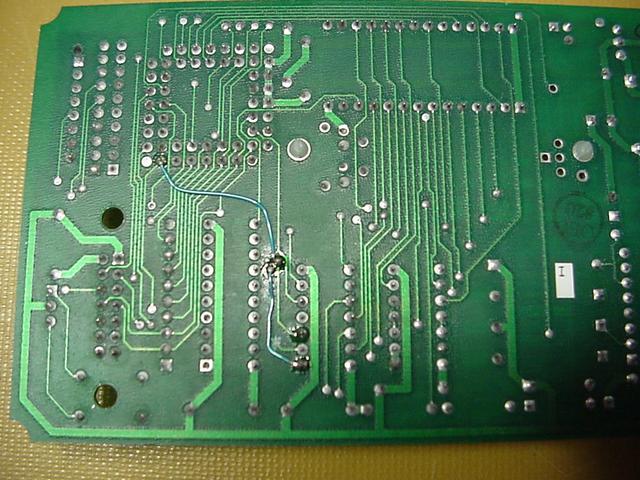

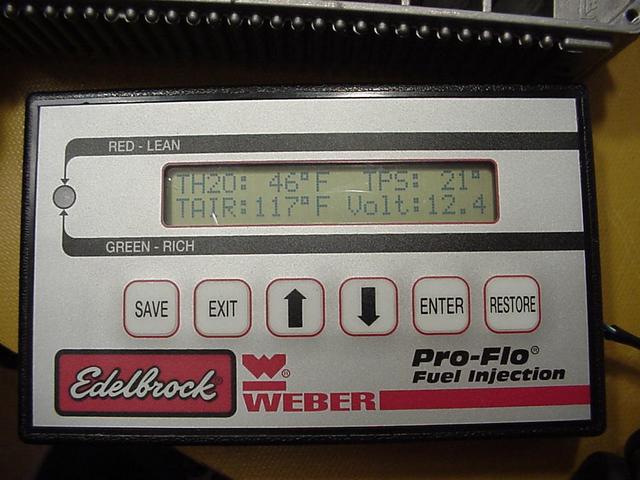

One of our design goals here was to set this new ECM and wiring up in such a way that the original Weber ECM would still work in the vehicles. So one thing that needed to happen was that the original Weber ECM would need some modifications to be compatable. For instance the new ECM is fully sequential and the Weber fired a pair of injectors at a time (the Weber ECM originally was for a four cylinder car). This required that the original injector driver outputs to be jumped to the newly defined connector pins. There were numerous other pins that also needed to be cleared and sometimes connected else were. Another thing that we did is to remove the double inversion in the serial lines. The original Weber setup inverted the serial lines for some reason so a special cable was required to connect a laptop to the ECM. On the new ECM we designed our serial interface with standard polarity. We wanted to use the Edelbrock supplied hand held with our new ECM so we need to remove the extra inversion from both units.

Notes on main ECM plug wiring....

Input Pin:

1 Gnd - No change

2 O2 - No change

3 Inj #8 - Was Crank Trigger Return........

ECM - Cut ground and tie to J1-35

Conn - Brown-16 to this pin (J1-3)

Wire that was on this pin (Yellow-18) to J1-5

4 CAM Index - No Change

5 CAM/Crank Return -

Conn - Leave wire that is now on it and attach wire

that was on J1-3 to it.

6 O2 return -

ECM - Assure this in is clear

Conn - Green-18 to this pin

7 Oil Sensor -

ECM - Assure this pin is clear

Conn - White-18 - Right Rocker to Dash & oil pressure gauge

8 Serial Receive Data -

ECM - Remove inversion

Conn - No Change

9 Speedo Input -

ECM - Assure this pin is clear

Conn - Blue-18 from speedo pickup

10 Fuel Pump Relay -

ECM - Clear pin then tie to J1-28, org Main Power Relay

Also jumper to J1-13

Conn - Move Tan/Wht wire from J1-28 to J1-10

Will be using the original relay as the fuel pump

only relay now.

11 Sensor Ground Return - No change

12 Coolant Fan Relay -

ECM - Assure this pin is clear

Conn - Yellow-18 wire up right rocker to front coolant relay

13 Compressor Relay -

ECM - Assure this pin is clear. Jumper to J1-10 & J1-28.

Conn - Yellow-18 to low side of compressor activate relay.

This relay will supply power to the SPDT switch in

the battery compartment which directs control power

to the compressor relay and it will supply the control

signal to the vacuum pump control circuit.

14 Reverse Lockout Relay -

ECM - Assure this pin is clear

Conn - Yellow-18 to reverse vacuum solenoid

15 MAP Sensor - No change

16 INJ-#5 -

ECM - Clear this pin and tie to J1-18

Conn - Move wire that was on J1-18 to this pin (screwed up!)

17 TPS Sensor - No Change

18 INJ-#6 -

ECM - No Change

Conn - Move original wire (Black/Red) to J1-16

Blue-16 to this pin

19 Gnd - No change

20 ECU Power - No change

21 INJ-#3 -

ECM - Assure this pin clear and tie to J1-33

Conn - Black-16 tied to this pin

22 INJ-#2 -

ECM - Assure this pin clear and tie to J1-32

Conn - Red-16 tied to this pin

23 Crank Trigger+ - No change

24 Key on Sense -

ECM - Assure this pin is clear. Internally need to tie

47 ohm emitter resistor to ground.

Conn - Blue-18 to ignition switch - pre diode!

Remove the wire that was there and leave free. This wire

will cause a ground loop if tied to ground, so what to do

with it??????????????

Removed wire (blk-18) from plug trying to get enough

room to install hood.

25 SA Output - Ignition Amp Trigger -

ECM - Install a 2.7k resistor to +5 Vref

Conn - Remove 2.7k to +5 Vref

26 Ignition B spare output

ECM - Ok to leave as is.

Conn - Orange-18 wire out and mark as spare ignition output

27 Serial Transmit Data -

ECM - Remove inversion from signal

Conn - No change

28 Injector/IAC Relay

ECM - Tie this pin to J1-10 and J1-13

Conn - Green-18 wire to new INJ/IAC Relay

29 COOL Sensor - No change

30 +5 Vref Output - No change

31 MAT Sensor - No Change

32 INJ-#7 -

ECM - Tie this pin to J1-22

Conn - No change

33 INJ-#4 -

ECM - Tie this to pin to J1-21

Conn - No change

34 IAC Motor - No change

35 INJ-#1 -

ECM - Tie this pin to J1-3

Conn - No change

| Pin | ECM #IAW4W6 | With Crank Trigger | MPC555 ECM |

|---|---|---|---|

| 1 | Ground | Ground | Ground |

| 2 | O2 Sensor | O2 Sensor | O2 Sensor |

| 3 | N/C - (Gnd) | Crank Trigger- (Gnd) | Injector #8 |

| 4 | N/C - (magnetic input) | CAM Position+ | CAM Position+ |

| 5 | Dist Return (Gnd) | CAM Position- (Gnd) | CAM/Crank Return (Gnd) |

| 6 | N/C - (Gnd) | N/C - (Gnd) | O2 Ret to Differential NBO2 |

| 7 | N/C - (CA3262E-8) | N/C - (CA3262E-8) | Oil Pressure Sensor |

| 8 | ECM Serial RX | ECM Serial RX | ECM Serial RX |

| 9 | N/C - AN1 Input | N/C - AN1 Input | Speedometer Input |

| 10 | Diode Protection | Diode Protection | Fuel Pump Relay |

| 11 | Sense Return (Gnd) | Sense Return (Gnd) | Sense Return (Gnd) |

| 12 | N/C - (CA3262E-3) | N/C - (CA3262E-3) | Coolant Fan Relay |

| 13 | N/C - (PAL-2 input) | N/C - (PAL-2 input) | Compressor Relay |

| 14 | N/C - (PAL-1 input) | N/C - (PAL-1 input) | Reverse Lockout Relay |

| 15 | MAP Sensor+ | MAP Sensor+ | MAP Sensor+ |

| 16 | N/C - (Current Driver) | N/C - (Current Driver) | Injector #5 |

| 17 | TPS Sensor+ | TPS Sensor+ | TPS Sensor+ |

| 18 | INJ-B (6&5) | INJ-B (6&5) | Injector #6 |

| 19 | Ground | Ground | Ground |

| 20 | ECM Power (+12 Relay) | ECM Power (+12 Relay) | ECM Power (+12 Relay) |

| 21 | N/C - (A/C sense) | N/C - (A/C sense) | Injector #3 |

| 22 | N/C - (HY2 / AN0) | N/C - (HY2 / AN0) | Injector #2 |

| 23 | Dist Trigger+ | Crank Trigger+ | Crank Trigger+ |

| 24 | Ignition Return (SA-) | Ignition Return (SA-) | Key On Sense |

| 25 | Ignition Output (SA+) | Ignition Output (SA+) | Ignition Output (SA+) |

| 26 | N/C - Ignition Output | N/C - Ignition Output | Ignition B Output (spare) |

| 27 | ECM Serial TX | ECM Serial TX | ECM Serial TX |

| 28 | Fuel Pump Relay | Fuel Pump Relay | Injector/IAC Power Relay |

| 29 | COOL Temp Sensor | COOL Temp Sensor | COOL Temp sensor |

| 30 | +5 volt Reference | +5 volt Reference | +5 volt Reference |

| 31 | MAT Sensor+ | MAT Sensor+ | MAT Sensor+ |

| 32 | INJ-D (2&7) | INJ-D (2&7) | Injector #7 |

| 33 | INJ-C (4&3) | INJ-C (4&3) | Injector #4 |

| 34 | IAC Motor | IAC Motor | IAC Motor |

| 35 | INJ-A (1&8) | INJ-A (1&8) | Injector #1 |