Filler Neck Installation

Locating the fill neck was a critical operation. When I installed the original tank many years ago I cut the hole in the gas tank

cover to fit the tank. This time I had to hit that hole dead on. No grinding this time after it is painted. Basically made a jig that located

off of a common mounting hole that wrapped around the original filler neck. Then using this jig I fit the new neck to the tank. Not so easy to

do because stainless is tough stuff to work with.

| The locating jig off of the common mounting bolt hole. |

|

| With the new tank in tha car needed to verify that it would fit the cover. |

|

| Cutting the hole into the tank. A real thrill into stainless and several angles. Turned out nice though. |

|

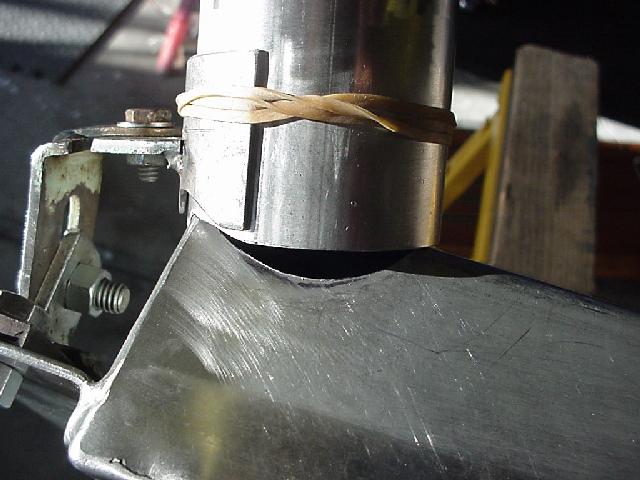

| Fitting the neck to the multiple angles. Another fun job of grinding. |

|

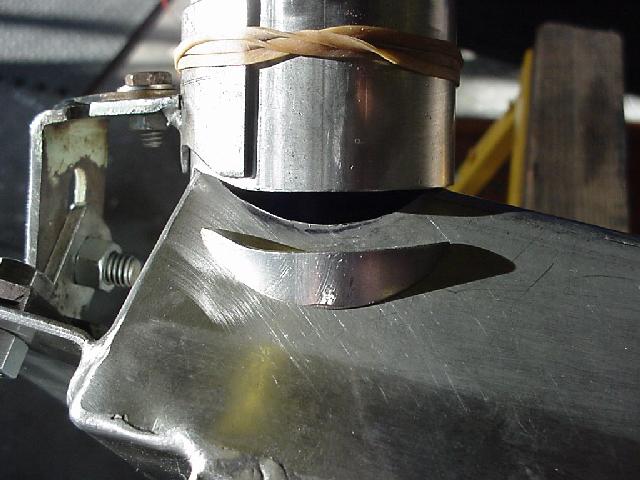

| To keep the neck long enough to fill the tank completely needed to make a sliver of steel to fill the gap.

I was able to miter the rest of the tubing so there was no gaps but this was a little too much to bridge.... |

|

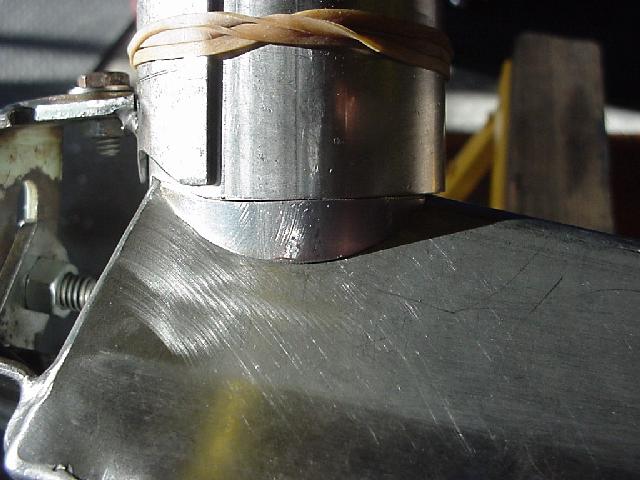

| A few minutes with the TIG and it is all sealed. |

|