Stainless Steel Fuel Tank

Well finally got tired of worrying about when

either the main Mallory fuel pump or the surge tank feeder pump (Holley

Red pump) would give out. The surge tank worked well for keeping

the main pump fed with fuel when going around turns but still had a

vapor lock at high altitudes and temperatures. Fuel would still

boil in the 18 inch line between bottom of the surge tank and the

intake of the high pressure pump. With the extremely limited life

of the brushes in the Mallory pump and the very poor quality of the

Holley feed pump the writing was on the wall, which one of them would strand me first....

The only real answer was to place the pump

inside of a baffled tank. I first looked into modifying my

original tank to fit an in-tank pump. A couple of items concerned

me. First was welding on a tank that had fuel in it and the other

was what was going to happen to the POR-15 coating on the inside of the

tank during the welding process. I wasn't to excited about doing

the welding myself. Tanks Inc., the manufacture of the original

tank, would do it. They basically said the 'most of the times

they don't blow'. Yikes, I don't want to around on one of those

bad days! What really made up my mind was the coating.

Welding in the flange and baffle would certainly damage the coating

inside of the tank with no good way to repair it. Just didn't

want a bunch of flaky junk clogging up that little inlet screen.

Finally decide to go with a stainless tank from Rock Valley. They

worked with me on optimizing the tank volume and neck placement.

I started with the dimensions of their 20 gallon tank. I made a

wooden jig that outlined these dimensions. Getting around the

2.5" exhaust pipes, which were built around the old tank, was a big

concern. I was able to take a little from here and add a little

their. Finally got a set of dimensions that would fit. The

total volume ended up just shy of 23 gallons. Because I had to

hit the hole in the gas tank cover exactly in the center there was no

way that they could have installed the filler neck. They sent it

along and I fitted to the car.

The fuel pump is a Walbro GSS340 255lt/hr high

pressure unit. The workmanship on the tank for the most part was

excellent. The only two nits where they didn't clean the inside

of the tank and who ever taped the sender holes was hung over something

fierce. You could do a better job of getting them straight if you

closed your eyes. They were so far off there was no way to ever

get the sender installed. As far as following my

drawing the dimensions were exactly as specified. If it

didn't fit it would not have been their fault.

Filler Neck Installation

Filler Neck Installation

| The original Tank. |

|

| A view of the vent system and original plumbing. The AN-4 is the venting system and the visable AN-6 hard line is the return. |

|

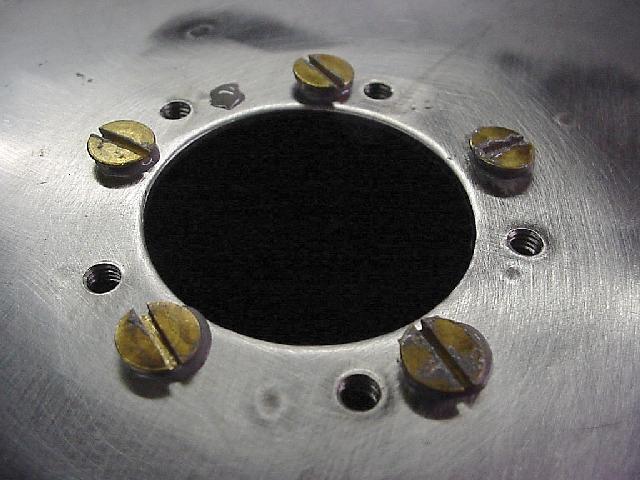

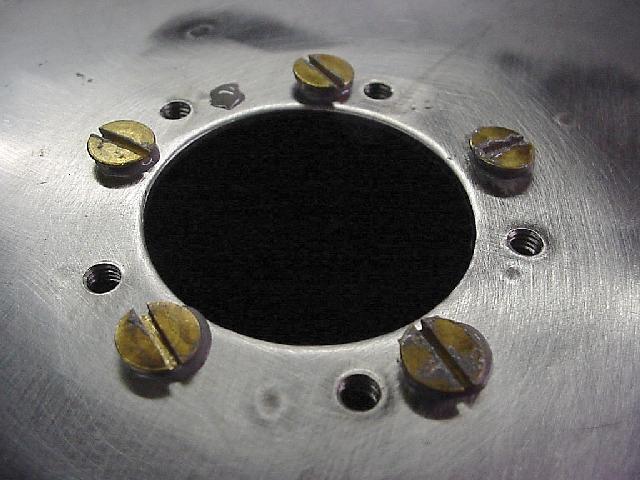

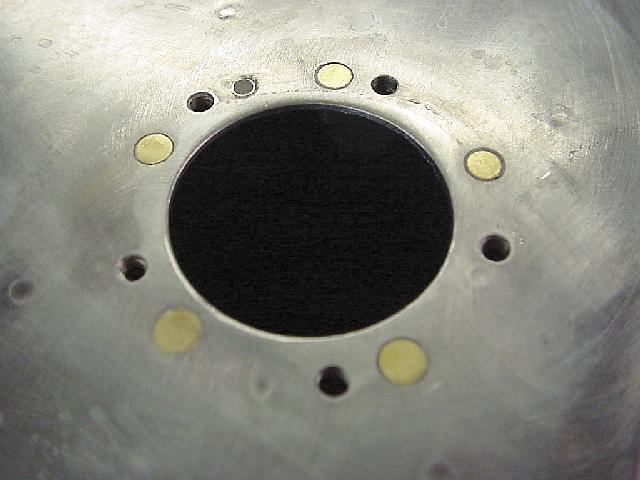

| Nice job of taping the holes

for the fuel level sender. So far off the you couldn't install

the sender. |

|

| I found that I could rotate the VDO sender mounting plate. So I located the new hole

pattern and tapped them straight! Next I countersunk the holes I wanted to not keep. |

|

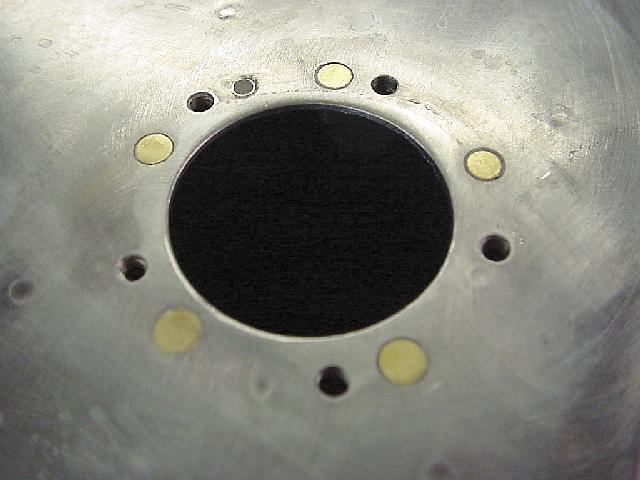

| Next I filled the theads and the area below the countersink with JB-Weld. Installed some brass

flathead screws and let setup for a day or so. |

|

| After a little grinding and sanding ended you with a nice smooth sealed surface

again. Shouldn't have to have done this as much as this tank cost to build! |

|

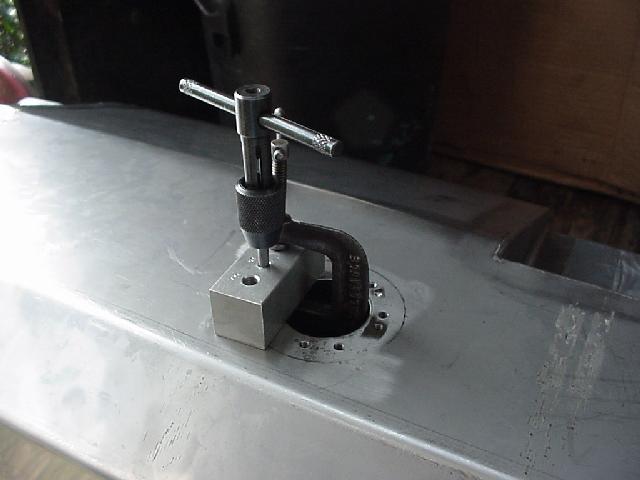

| Next I needed a couple hard points to run the feed and return lines to. There wasn't much room

between the front of the tank and the rear crossmember, and of coarse this was the only place to run the lines. Needed to make these

90's so that they wouldn't turn by themselves. I could only get a single wrench up into the restricted space to thighten the tube nuts.

|

|

| The fuel pump assembly with the Walbro GS340 pump. One thing that was a royal pain was how close

they put the the 1/4" pipe fittings. There was just not quite enough room to swing a 90 degree AN-6 fitting. Another 1/16" is

all that was needed! |

|

| Plumbing between tank and hard points mounted on the floor pan. |

|

| Final test fit into the car. Some tight clearance between suspension and exhaust. |

|

| A final pressure test before powder coating just to be sure there were no surprises. |

|

| Powder coated and ready to install for the last time. |

|

| In the car for the final time... Or at least till the next time it comes out! |

|

Filler Neck Installation

Filler Neck Installation