|

|

|

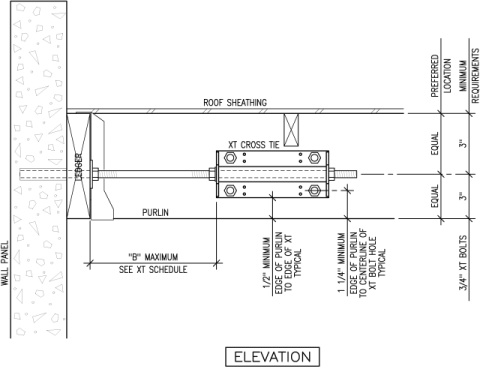

The XT Cross Tie is a connection device that was designed and developed as a highly improved alternate to holdown type connection devices for use in wall anchorage and diaphragm cross tie installations in tilt-up buildings. The XT Cross Tie is also applicable to other types of buildings of similar construction.

- Paired Installations: The XT Cross Tie is specifically designed to be used in paired installations. The XT Cross Tie may also be used for single sided applications as well.

- Integrated Drill Guide: The XT Cross Tie is designed to accept an integrated Drill Guide. The Drill Guide quickly snaps onto the XT Cross Tie during installation, and allows the bolt holes to be accurately drilled, thus eliminating, or highly minimizing the potential for oversized and/or back-drilled bolt holes, and maximizing the load deformation performance of the overall connection. All of the standard XT Cross Ties are designed to be installed with one universal Drill Guide. In addition, the use of a drill guide typically allows for faster installations, which generally allows for reduced installation costs.

- Bi-directional Load Capacity: The XT Cross Tie was specifically designed to resist loading bi-directionally. This allows connections to be designed to resist both tension and compression loads (through use of the rod as a tension and compression element).

![]()

- COLA Load Deformation Capacity Criteria: The load capacity of the XT Cross Tie is not limited by the COLA Load Deformation Capacity Criteria (load required to produce an 1/8" of device deformation on a steel test jig divided by three). Allowable loads are based on the capacity of the fasteners in wood..

- Ductile Bolt Failure Mode: The standard XT Cross Tie is designed to be installed with only 3/4" bolts in 2, 4, 6, or 8 bolt configurations (and with rod sizes of 3/4", 1", and 1-1/8"). This allows the standard XT Cross Tie to be used in 4x timber elements (and larger) and still provide for a ductile bolt failure mode (l/d > 4.5), while minimizing the total number of bolts required in a connection. For paired installations the difficulty associated with aligning all of the bolt holes with each other increases substantially with each additional bolt hole that must be drilled, and thus it is important to minimize the number of bolts in a connection in order to simplify installation.

- Rod Offset Distance: The XT Cross Tie was designed with a standard rod offset distance of ROD = 2.33". This rod offset distance allows for much easier installations by providing the clearance required in order avoid the interference problems that can occur between the rod element and most any purlin hanger encountered during purlin-to-wall and purlin-to-purlin diaphragm cross tie installations, such as in buildings with panelized roof framing systems. In general, a minimum rod offset distance of ROD = 2" is typically required in order to allow for sufficient clearance between the rod element and most purlin hangers that might be encountered during such installations. For connection devices with a ROD of less than 2", 1/2" to 3/4" plywood or timber padding is generally required to be installed in order to increase the rod offset distance to 2", or greater. This

![pict]() padding can be a costly addition, as it must be structurally attached or bonded or attached to the timber element in order for the installation to be considered a standard installation (and bolt capacity calculated per the NDS provisions), otherwise the plywood padding must be considered a gap or air space, which must be taken into account when evaluating the bolt capacity. padding can be a costly addition, as it must be structurally attached or bonded or attached to the timber element in order for the installation to be considered a standard installation (and bolt capacity calculated per the NDS provisions), otherwise the plywood padding must be considered a gap or air space, which must be taken into account when evaluating the bolt capacity.

- Deformation control. Capacity not limited by COLA.

- Load capacities between 8,380 lbs and 33,460 lbs (4x framing, paired, ASI = 1.33). Custom XT’s with 5/8” and 1” bolts, increased load capacity, and increased rod offsets are available.

|

|

|

Made in the USA |

|